PCO Series 3-roll variable axis plate bending rolls

PCO Features

The peculiar geometry of the PCO roll makes it possible to bend big thickness plates just increasing the distance between the lower rolls, in this way it is possible to have a heavy duty machine with a smaller structure compared to a traditional 3 or 4 roll plate bending roll.

Plus the PCO machine need limited foundations even for big thickness plates due to the reduced working height.

Rigid frame construction

without forces transmitted

to foundations

The 4 hydraulic cylinders that move the lower rolls are allocated inside the frame

Wired with light-cables

against electromagnetic

interference.

Centralized control panel, light weight design for easy handling

Rolls made of high resistance steel forgings, with large diameter and light cambering

Machine frame with linear guides for rolls sliding

To ensure the maximum rigidity and strength of the machine the uprights are connected by two heavy-duty H-beams fabricated frames.

Sliding support with high resistance antifriction material

maintenance free

Fully hydraulic drive with automatic speed compensation

Instantaneous brakes for rolls rotation for maximum safety factor

Digital control of the rolls parallelism with proportional valves. Precision 0,1 mm (0,004”)

Heavy-duty turning bearing support, with four anti deflection points for maximum rigidity

Infinitely variable bending pressure of the top roll with digital pressure gauge

Heavy-duty and rigid frame design for maximum resistance for cone rolling

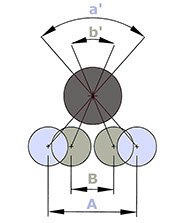

• TOP ROLL MOVEMENT:

The top roll move up and down on the vertical axis by high quality largely dimensioned hydraulic cylinders. All the hydraulic rams are ground, hard chrome plated and polished.

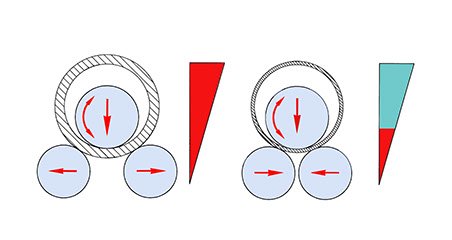

• LOWER ROLLS MOVEMENT:

The lower rolls are moving independently one from the other on the horizontal axis by high quality largely dimensioned hydraulic cylinders. All the hydraulic rams are ground, hard chrome plated and polished.

The PCO allow to change the geometry between the bending rolls and this give at the operator the maximum flexibility to adjust the machine for a wide variety of rolling works (pre-bending, cone pressing, rolling, shell calibration etc....).

The possibility to adjust the distance between the two lower rolls increase the flexibility and the thicknesses range the can be rolled on the machine:

This allows to roll heavy wall thickness plates (max. centerline distance) while with the lower rolls very close each other (min. centerline distance) you will obtain an optimal plate feeding for thin plates.

Quick Links

Products

About us

Copyright © 2016 PARMIGIANI MACCHINE. All Rights Reserved.

World

Headquarters

PARMIGIANI MACCHINE

Via Sesto, 44

26100 Cremona

Italy

Tel +39 0372 216.39

Fax +39 0372 457.814

E-mail:

info(at)parmigiani.net

One name. One Family. One Company. Since 1927.